In the intricate world of costume manufacturing, achieving excellence is no small feat. This industry requires a meticulous approach, especially when it comes to mascot costumes that are often the face of a brand or organization. The quest for quality in this domain involves stringent adherence to standards that go beyond mere aesthetic appeal.

One of the fundamental aspects of maintaining high standards in costume manufacturing is the use of superior materials. Mascot costumes, in particular, need to be durable and comfortable, given their frequent use at events and public appearances. Quality fabrics that can withstand rigorous use while providing comfort to the wearer are paramount. This ensures longevity and reduces the need for frequent replacements.

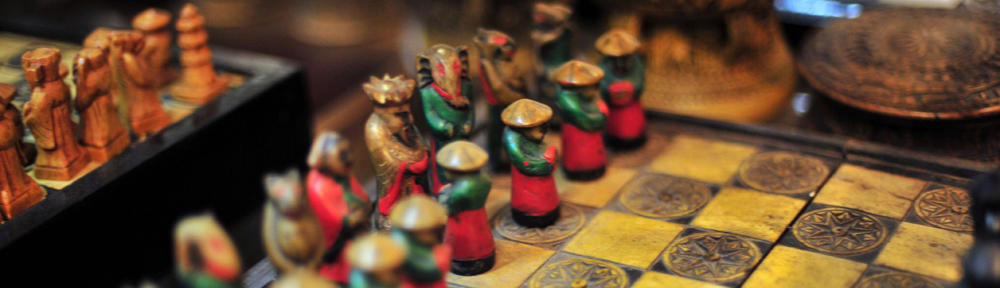

Craftsmanship plays a crucial role in the pursuit of excellence. Skilled artisans who possess an eye for detail are indispensable. Each stitch, seam, and embellishment must be executed with precision to ensure the costume not only looks impressive but also functions well. For mascot costumes, attention to the minutiae such as joint flexibility and ease of movement is essential, as they are often worn by performers for extended periods.

Technological advancements have significantly influenced standards in costume manufacturing. Computer-aided design (CAD) software allows for precise pattern making and customization, ensuring that each costume fits perfectly. Additionally, innovative techniques like 3D printing have revolutionized the way props and intricate designs are incorporated into costumes, enhancing both accuracy and efficiency.

Another critical factor in maintaining high standards is the process of quality control. Rigorous testing protocols are implemented to ensure that each costume meets the expected criteria. This includes stress tests, color fastness checks, and wearability assessments. For mascot costumes, these tests are particularly vital as they must endure various environmental conditions, from outdoor events to indoor arenas.

Customer feedback is an invaluable resource in the quest for manufacturing excellence. By continuously gathering insights from users, manufacturers can make informed adjustments and improvements. This feedback loop helps in identifying potential issues early on and fine-tuning the production process to better meet customer expectations.

Environmental sustainability has also become a significant consideration in modern costume manufacturing. Using eco-friendly materials and adopting sustainable practices not only aligns with global trends but also sets a standard of responsibility within the industry. Mascot costumes produced with sustainable practices contribute positively to the brand’s image and resonate well with environmentally conscious consumers.

In conclusion, the journey towards achieving excellence in costume manufacturing is multifaceted, involving high-quality materials, skilled craftsmanship, technological innovation, rigorous quality control, responsive feedback mechanisms, and sustainable practices. For mascot costumes, these standards are particularly critical as they represent brands in the most visible manner. As the industry continues to evolve, these benchmarks will undoubtedly play a pivotal role in shaping its future.